compression test elastomer|compression test diagram : manufacturer ASTM D395-18. Standard Test Methods for Rubber Property—Compression Set. Significance and Use. 4.1 Compression set tests are intended to measure the ability of rubber compounds to retain elastic properties after prolonged action of compressive stresses. webnicolebun OnlyFans Pics. Download over 8,000,000 adult amateur porn fetish sex hardcore movies, videos and clips. 1,100 fetish categories, 50,000 different studios. The largest .

{plog:ftitle_list}

WEB31 de dez. de 2020 · Pena Ajena. Season 1. Jesús y Nuria llevan días sin tener relaciones sexuales porque ella está esperando su ovulación para tener un bebé. Los padres de .

ASTM D395-18. Standard Test Methods for Rubber Property—Compression Set. Significance and Use. 4.1 Compression set tests are intended to measure the ability of rubber compounds to retain elastic properties after prolonged action of compressive stresses. Several test methods exist for quantifying the compression set of elastomers. Two common test methods are ASTM D-395 and ASTM D-1414. Both test methods use the same .Compression set is often a property of interest when using elastomers. Compression set is the amount of permanent deformation that occurs when a material is compressed to a specific deformation, for a specified time, at a specific temperature. ASTM D395 Standard Test Methods for Rubber Property—Compression Set is the test method used and it .

2.7 Experiments. Experimental data of nine unfilled rubbers from quasi-static, uniaxial tensile tests as well as confined compression tests are employed, see Table 4, Fig. 1 and [].The uniaxial test data are used for the parameter identification of the \(\bar{I}_1\)-dependent strain energy functions \(W_{\textrm{iso},1}\) in Sect. 4.2, whereas the volumetric strain energy functions \(W_\textrm .

Abstract. The bulk modulus represents a material's resistance to volume change when subjected to pressure loading. Determination of bulk modulus is important for evaluation of applications where compression is involved. Most methods proposed for this purpose are complicated and costly. A simple method is to compress an elastomer button, fully confined in .The compression set (ASTM D395) of a material is the permanent deformation remaining after compressing it. [1] In specific methods, temperatures and percent compression are specified. The term is normally applied to soft materials such as elastomers and foams. Compression is normally measured in two ways: compression set A and compression set B. [2]

According to the standard of elastomers compression test, ASTM D 395-03, the standard dimensions of a specimen are: thickness – 12.5 ± 0.5 mm and diameter – 29.0 ± 0.5 mm. The compression test of elastomer specimens was achieved with a Controlled Electro Mechanism Universal Testing Machine WDW. The

Type 1 specimens for Test Method A and Test Method B. A similar mold but having a cavity of 6.3 6 0.3 mm (0.25 6 0.012 in.) in thickness and 13.3 6 0.1 mm (0.52 6 0.004 in.) in diameter will provide Type 2 specimens for Test Method B. 5.4 When the standard test specimen is to be replaced by a specimen taken from a vulcanized rubber part of greaterASTM D575 test method A is a procedure for determining the compression-deflection of rubber compounds (except hard rubber and sponge rubber). ASTM D575 is useful in comparing stiffness of rubber materials in compression. They can be used by rubber technologists to aid in development of materials for compressive applications. ASTM D575 test method A is a . The 3 most common durometer gauges used to measure rubber are Type A, Type M and Type D. Type A is used to test soft rubber materials while Type D is used to test hard rubber and plastic materials. Type M, also for soft materials, was developed to test small specimens, typically O-rings, that do not meet the physical size requirements specified .

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests consists of a load cell, a crosshead(s), compression test tools, electronics, and a drive system.It is controlled by testing software used to define . Compression Set Jig: Cured Rubber: ASTM D395: DMA. . In a flex fatigue test, a rubber sample is subjected to repetitive cyclical bending at low stresses for set number of cycles. Often, this is performed at an elevated temperature to further accelerate the fatigue. This ongoing motion initially causes micro-cracks to form in the rubber, which .Elastomer Sample in Bending on DMA Q800 l l l l l l l l l l l l l l p p p p p p p p p p p p p p p & 0.1 0.2 0.3 [ ] Tan Delta 1 10 100 1000 10000 p [ ] Loss Modulus (MPa) 1 10 100 1000 10000 l [ ] Storage Modulus (MPa)-100 -75 -50 -25 0 25 50 75 100 125 7HPSHUDWXUH & Sample: Black Rubber Size: 17.5000 x 12.9700 x 1.0700 mm Method: Temperature .

This study is based on cyclic compression tests of the three elastomer types mentioned above, using materials with similar hardness. . (ISO 815-1:2019), which is the permanent set after a long compression duration. In this study, the test duration is short and CS is an instant value after unloading, .Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .The compression experiment is also a popular test for elastomers. When testing for analysis, pure states of strain are desired and this is especially difficult to achieve experimentally in compres- . Figure 9, A Volumetric Compression Fixture with Specimens from test to test. While it is reasonable to assume that variation

ASTM D575 – Standard Test Methods for Rubber Properties in Compression: This standard describes the methods for testing the compressive properties of rubber, both heats and cooled. ASTM C773 – Standard Test Method for .Download scientific diagram | Standard compression test on a silicon rubber cylinder from publication: Inverse-FEM Characterization of a Brain Tissue Phantom to Simulate Compression and .

Compression set is the most commonly tested property for elastomeric gaskets/rubber materials. Test data can be found on most product datasheets. It is fair to infer that material with good compression set .Compression set testing is used to determine the ability of elastomeric materials to maintain elastic properties after prolonged compressive stress. The test measures the somewhat permanent deformation of the specimen after it has been exposed to compressive stress for a set time period. This test is particularly useful for applications in .The Compression Set Test. The compression set is usually tested according to the standards ISO 815-1, DIN ISO 815-1 (this replaces DIN 53517, which is still noted in old data sheets or specifications) or ASTM D395. . This detailed technical report tells you more about compression set testing of elastomers, CS test devices, the purpose of the .The amount of compression that is not fully recovered within the time scale of the experiment is known as set. Thus the significanceof set in sealing applications is clear: when the mating Correlation between Compression-Set and Compression Stress-Relaxation of Epichlorohydrin Elastomers A. Wahab* # and A.S. Farid**

Thermoplastic elastomer vulcanizate (TPV) and liquid silicone rubber (LSR) are replacement candidates for ethylene-propylene-diene rubbers (EPDM), as they offer the possibility for two-component injection moulding. In this study, these material types were compared side by side in cyclic compression tests. The materials were also characterized to provide details on .The 2015 global market for elastomers is estimated at between -50B. Solution: The compressive properties of rubber are tested using compression platens. Sandpaper may be used in between the platens and the sample in order to reduce the occurance of slippage. For this test, the rubber sample is compressed to a pre-specified deflection percentage.COMPRESSION SET. Test Standard: ASTM D 395 – Method B Aim: After a force is applied to the thermoplastic elastomer material in different time and temperatures, ability to prevent elastic properties of material is measured.The permanent deformation remaining is measured after applied some pressure in a known temperature and time. Test Device: Compression Set .

New test rig components for faster development and validation; . As an example, the figure below shows the compression set of a soot filled elastomer at an aging temperature of 110 °C. The aging took place under normal air atmosphere as well as nitrogen atmosphere. The compression set increases faster during aging under air atmosphere than . 3.1.2 Test Method B Compression Test at Speci ed Force A compression test in which the speciÞed mass or compressive force is placed on the specimen and the resulting deßection is measured and recorded. 4. Signi cance and Use 4.1 These test methods are useful in comparing stiffness of rubber materials in compression. They can be used by rubber In simple terms, compression force deflection describes how a rubber material compresses under a given force. A note on deflection: Customers can often refer to deflection as compression. We always recommend keeping the terms separate. An easy way to remember this is the following: Compression is a force, or something you DO.

http://tinius-5st.com/

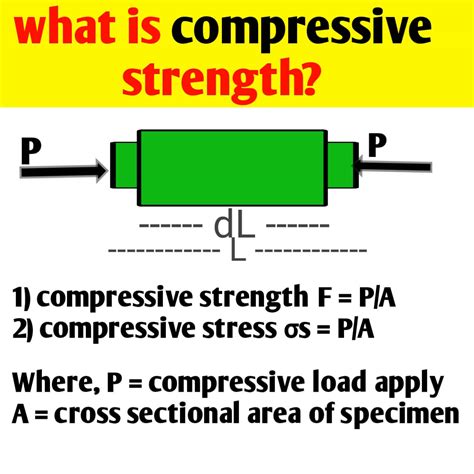

what is compressive strength test

what is compression testing machine

universal testing machine compression test

Resultado da Na Hora da Virada é um filme dirigido por Sanaa Lathan com Jamila C. Gray, Method Man. Sinopse: Como filha de uma lenda do hip-hop underground que morreu pouco antes de .

compression test elastomer|compression test diagram